ABSTRACT

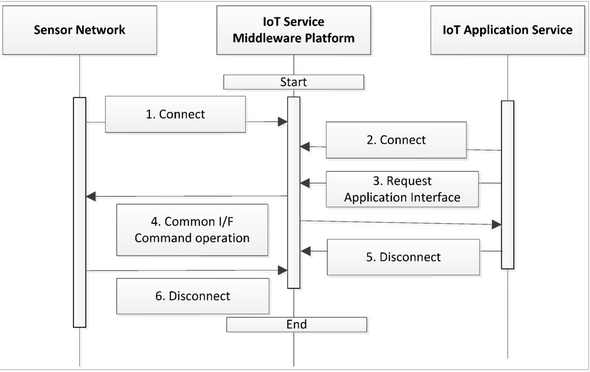

The so-called Internet of Things (IoT) has attracted increasing attention in the field of computer and information science. In this paper, a specific application of IoT, named Safety Management System for Tower Crane Groups (SMS-TC), is proposed for use in the construction industry field. The operating status of each tower crane was detected by a set of customized sensors, including horizontal and vertical position sensors for the trolley, angle sensors for the jib and load, tilt and wind speed sensors for the tower body. The sensor data is collected and processed by the Tower Crane Safety Terminal Equipment (TC-STE) installed in the driver’s operating room. Wireless communication between each TC-STE and the Local Monitoring Terminal (LMT) at the ground worksite were fulfilled through a Zigbee wireless network.

LMT can share the status information of the whole group with each TC-STE, while the LMT records the real-time data and reports it to the Remote Supervision Platform (RSP) through General Packet Radio Service (GPRS). Based on the global status data of the whole group, an anti-collision algorithm was executed in each TC-STE to ensure the safety of each tower crane during construction. Remote supervision can be fulfilled using our client software installed on a personal computer (PC) or smartphone. SMS-TC could be considered as a promising practical application that combines a Wireless Sensor Network with the Internet of Things.

SENSOR NETWORK AND ANTI-COLLISION ALGORITHM FOR TOWER CRANE GROUP

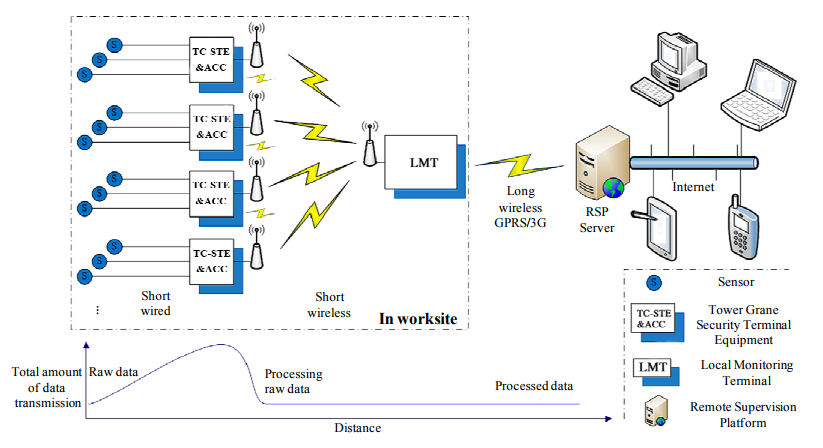

Figure 2. Sensor network and data transmission of safety management system for tower crane groups (SMS-TC)

LMT, Local Monitoring Terminal; TC-STE, Tower Crane Safety Terminal Equipment; ACC, Anti-Collision Controller; RSP, Remote Supervision Platform.

As a typical practical application of IoT in the field of construction industry, SMS-TC has a typical comprehensive sensor network, which consists of a short wired signal line, short wireless Zigbee network, long wireless GPRS/3G communication and Internet, as shown in Figure 2. In order to detect the operating status of each tower crane and its trolley, six sensors were employed and directly connected to TC-STE via a short wired signal line.

They are the horizontal and vertical displacement sensors for the trolley, the angle sensor for the jib, and the load, tilt and wind speed sensors for the tower, respectively. The wired signal lines can guarantee the stability of high-speed transmission for the raw data obtained from these sensors. ACC was integrated in TC-STE to process the raw sensor data. Only processed raw data were transmitted to the LMT via the short wireless Zigbee network.

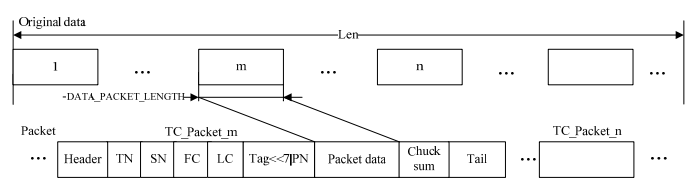

Len presents the length of data; the sender takes use of “DATA_PACKET_LENGTH” to split the data into [Len DATA_PACKET_LENGTH] TC_Packets. For each TC_Packet, Header and Tail are the head and tail information, respectively. TN represents the netID of source node; SN represents the netID of target node; FC represents the data type; LC represents the directive No.; Tag is the last TC_Packet; PN represents the serial number of multiple TC_Packets; Chuck sum is check information. The receiver restructures the packets according to PN, and it can recover the original data.

SAFETY MANAGEMENT SYSTEM FOR TOWER CRANE (SMS-TC)

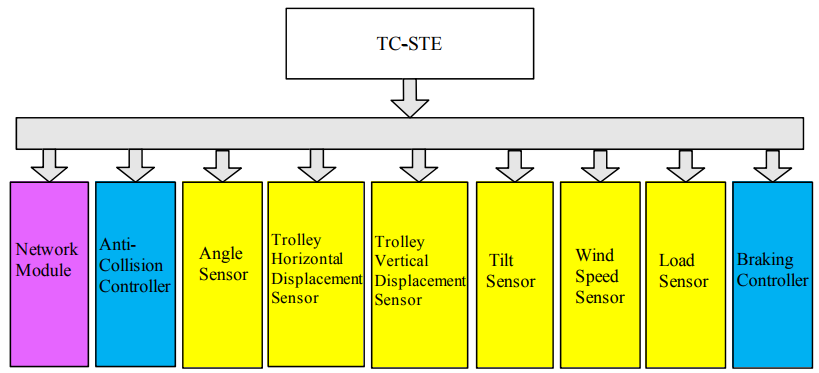

Purple box represents the network module; blue boxes represent controllers; yellow boxes represent sensors. The network module’s function is bidirectional communication with the LMT. It reports the real-time status of individual tower cranes to the LMT, which includes the position of the trolley, the angle of the jib, and the load, tilt and wind speed sensor information. Meanwhile, it receives the real-time status of other adjacent tower cranes from the LMT. The anti-collision controller processes the raw data of the six special sensors and runs the anti-collision algorithm.

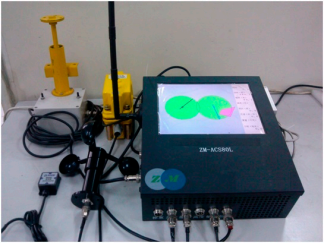

Figure 6. Tower crane safety terminal equipment (TC-STE) and the set of customized sensors

TC-STE acquires data from sensors at the key parts of tower crane, and then it can save and analyze these data, while it communicates through a wireless network to report the real-time status. According to the shared information of the LMT, the TC-STE can implement the alarming and braking tasks. For more details of the design and implementation of TC-STE, the physical picture and corresponding functional block diagram of the TC-STE are provided in Figures 6 and 7, respectively.

APPLICATION OF SAFETY MANAGEMENT SYSTEM FOR TOWER CRANE (SMS-TC)

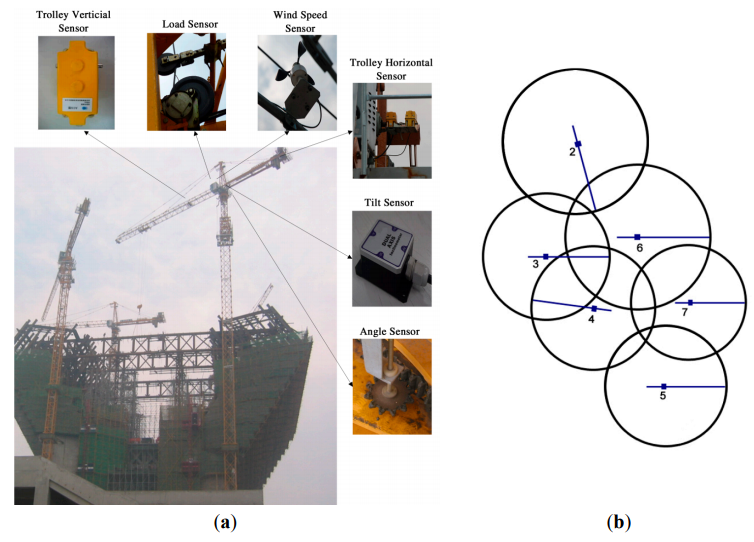

Figure 10.(a) The tower crane group in the worksite of Famen Temple Dagoba (FTD) and the actual assembled positions for six types of sensors; and (b) Schematic plan of a tower crane group. Number 2-7 represent six tower cranes with their netIDs

A real-time safety management system for tower crane groups was applied to a large-scale complex building worksite (Famen Temple Dagoba (FTD) in Baoji, Shaanxi Province, China) during its construction. FTD is like two hands clasped together with the height of 148m, which is equivalent to a fifty-storey building. Figure 10 illustrates the practical construction process of FTD. There are six tower cranes as a group within an overlapping working area.

Also shown in Figure 10a, six types of sensor were applied for measuring the real-time status of tower, jib and trolley. Taking tower crane No.4 as an example, the actual assembled positions of sensors are pointed out as well. Two displacement sensors are used to measure the horizontal and vertical position of the trolley. An angle sensor is used to measure the angle of the jib. The load sensor is used to measure the loading weight. The wind speed and tilt sensors are involved as well. In addition, the schematic plan of the tower crane group is shown in Figure 10b.

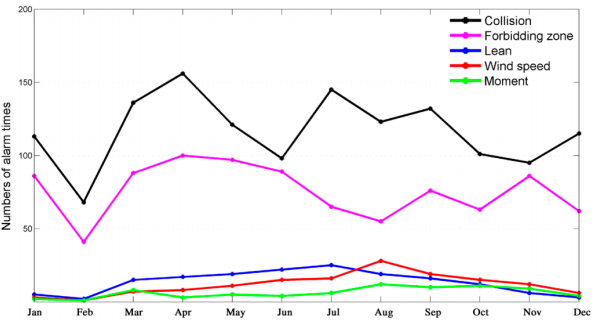

We record five types of alarm during the construction process, which include collision alarms, forbidden zone alarms, tilt alarms (or lean alarms), wind speed alarms and moment overload alarms. Figure 11 illustrates the number of alarms in each month during a year. Collision and forbidden zone alarms are the two most frequent types of alarms during the construction process, while the other three alarms are considerably less frequent.

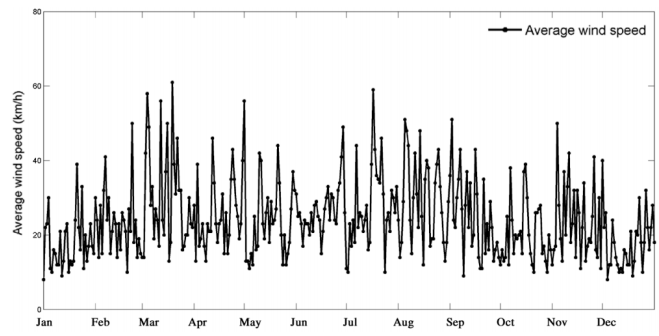

Figure 12. The average wind speed during the year 2013

In addition, utilizing the wind speed sensor, the SMS-TC can measure the wind speed in real-time and provide the average one during a day. Figure 12 depicts the average wind speed during the construction process. In the future, according to the data collected by load sensors, we can calculate the total weight of each tower crane in each day, so that the efficiencies of all tower cranes can be achieved to evaluate the work while it can also be utilized to improve the optimal layout of tower crane groups as an important reference.

CONCLUSIONS

In this paper, we have proposed a practical application combining a Wireless Sensor Network (WSN) and the nternet of Things (IoT) in the construction industry field, which was developed and named as Safety Management System for Tower Crane Groups (SMS-TC). The core components and softwares of SMS-TC were presented, respectively. The three main components could be roughly classified in the three layers of the IoT: Perception Layer, Network Layer and Application Layer. Additionally, as a supplement of the typical three-layer architecture of IoT, the SMS-TC has a fourth layer: Supporting Layer, which can fulfill the thinking, identifying and decision-making tasks as a functional brain of the IoT.

The SMS-TC sensor networks consist of a short-distance wired signal line, short-distance wireless Zigbee network, long-distance wireless GPRS and Internet. The advantages of this comprehensive network structure include that the total amounts of data transmission are significantly reduced in the wireless transmission phase, the energy consumption for the transmission is reduced and the energy conservation of the system is improved as well. A set of customized sensors are utilized to obtain the complex real-time status of each tower crane. The WSN is used to fulfill wireless communication between each tower crane and the Local Monitoring Terminal (LMT) at the ground worksite, which can avoid interruptions during the construction process and realize high-speed stable communication among the tower crane group.

Based on the global status data of the whole group, an anti-collision algorithm was executed to ensure the safety of each tower crane during construction. In order to facilitate remote supervision, LMT records the real-time data and reports them to the Remote Supervision Platform (RSP) through GPRS. Remote supervision can be fulfilled using our client software installed on a PC or smartphone. As a system with mechanics, electrics, algorithms and network communications all in one, SMS-TC could be considered as a practical application that demonstrates the promising prospects of WSN and IoT in China’s building industry and engineering in the near future.

Source: Xian Jiaotong University

Authors: Dexing Zhong | Hongqiang Lv | Jiuqiang Han | Quanrui Wei

>> Latest Sensor based IoT Projects for ECE Students

>> 200+ IoT Led Engineering Projects for Students

>> IoT Software Projects for Students

>> More Wireless Sensor Networks Projects Abstract for Engineering Students