ABSTRACT

The main causes of building defects are errors in the design and the construction phases. These causes related to construction are mainly due to the general lack of control of construction work and represent approximately 75% of the anomalies. In particular, one of the main causes of such anomalies, which end in building defects, is the lack of control over the physical variables of the work environment during the execution of tasks.

Therefore, the high percentage of defects detected in buildings that have the root cause in the construction phase could be avoidable with a more accurate and efficient control of the process. The present work proposes a novel integration model based on information and communications technologies for the automation of both construction work and its management at the execution phase, specifically focused on the flat roof construction process.

Roofs represent the second area where more defects are claimed. The proposed model is based on a Web system, supported by a service oriented architecture, for the integral management of tasks through the Last Planner System methodology, but incorporating the management of task restrictions from the physical environment variables by designing specific sensing systems. Likewise, all workers are integrated into the management process by Internet-of-Things solutions that guide them throughout the execution process in a non-intrusive and transparent way.

RELATED WORKS

Figure 1. State of the art of smart sensors and data collection technologies applied to the construction of residential buildings

As a synthesis of the studied literature, Figure 1 shows a graph summarizing the main fields of application within the field of residential building construction. The smart sensors and data collection technologies used in each work studied are also classified and graphed.

Although all technologies specified above improve the efficiency of construction projects from specific perspectives, none of those solutions are focused on improving the construction process itself through the control of internal and external variables. In addition, none of them propose improvements to the core process of residential building construction considering the monitoring of environmental variables, where most quality and efficiency problems originate.

PROPOSED MODEL

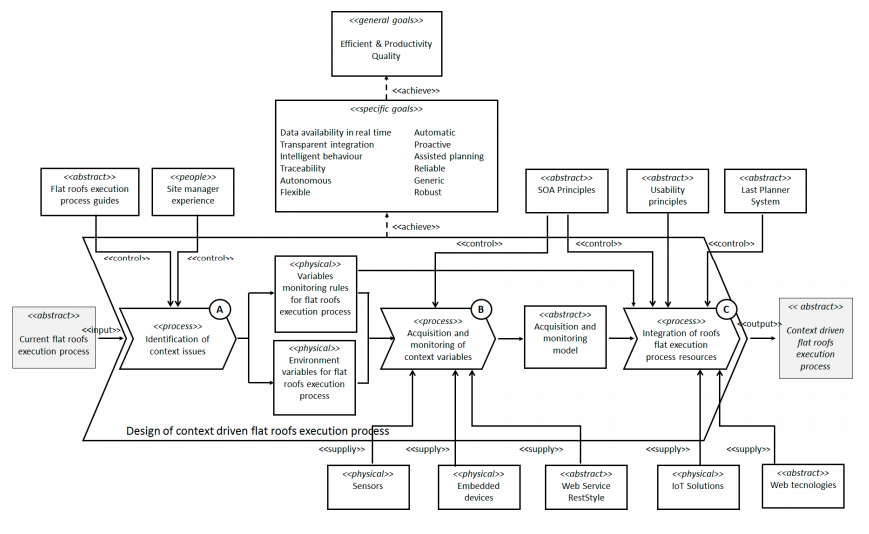

Figure 2. Modelling of the sub processes for achieving automated construction system through Eriksson-Penker notation

To achieve these strategic objectives (<specific goals>) represented in Figure 2, the controllers (<control>) and facilitators (<supply>) must be established to guide the transformation. Those represent strategies, paradigms, techniques and technologies that will be integrated into our proposal. The defined process will achieve the object model of this work in a systematic way, selecting the most appropriate techniques and tools to meet the objectives and thus solving the problems identified. In the proposed methodology, each of the tasks identified represents a stage of the investigation, and these will have associated one or more scientific methods as described below.

The transformation process that conducts the research has been divided into three phases or stages which are shown as three sub processes. The first sub process is denominated Identification of context issues (A in Figure 2).

The second of the sub processes named Acquisition and monitoring of context variables (B in Figure 2), aims to design an intelligent system for the acquisition and automatic monitoring of the context information identified in the previous sub process.

Finally, the third sub process named Integration of flat roofs execution process resources (C in Figure 2), aims to integrate all the actors and resources involved in the process to provide an assisted system for the execution of the process, and therefore, to avoid the current bad practices that origin defects.

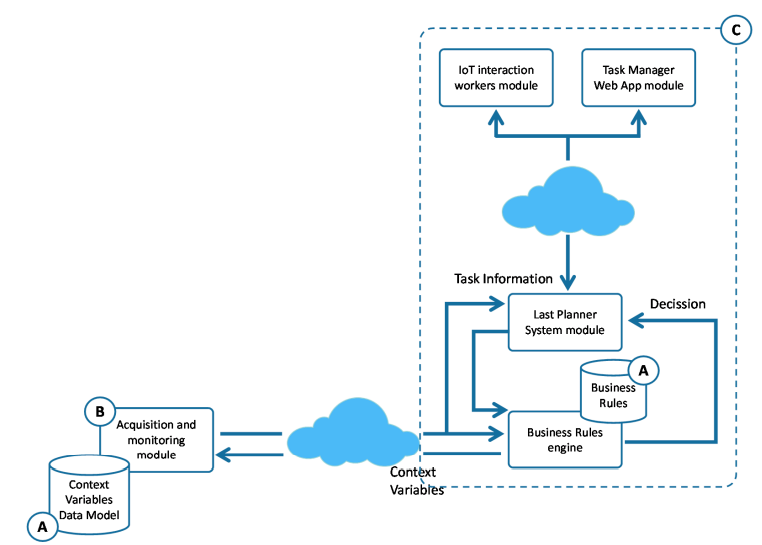

At this point information, technologies and human resources must be integrated in the process in a transparent way to achieve the previously stated objectives. As a result of all phases carried out at each stage of the research process, it is presented below the general architecture of the proposed model (Figure 3) which will be described in detail in the following sections.

IDENTIFICATION AND ANALYSIS OF DEFECTS

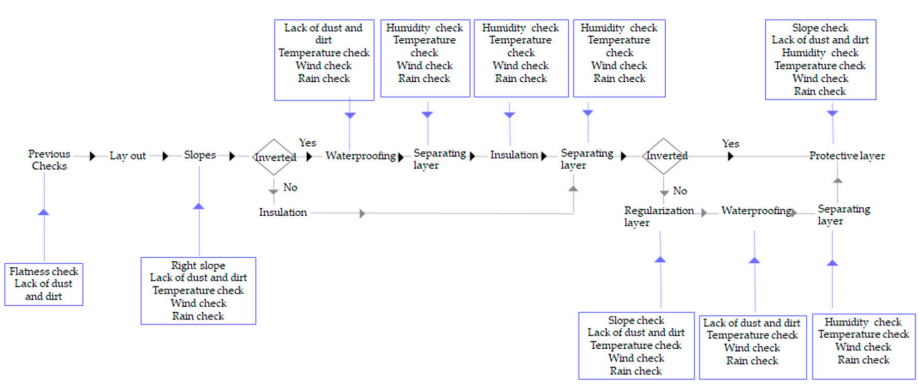

Accordingly, Figure 4 shows the main variables that affect the quality of the work during the construction process of walkable flat roofs whether they are traditional or inverted, i.e., the environment conditions together with the main essential requirements, for proper performance of activities to prevent future occurrence of deficiencies.

Some of these environmental variables relate to adverse weather conditions or just weather conditions incompatible with the works to be performed. These weather variables are rain, very high temperatures with excessive sun exposure, or very low temperatures below 50C that produce an excessive delay in the setting of mortars and concretes and therefore poor development of resistance, excess humidity, bursts of wind, etc.

ACQUISITION AND MONITORING OF CONTEXT VARIABLES

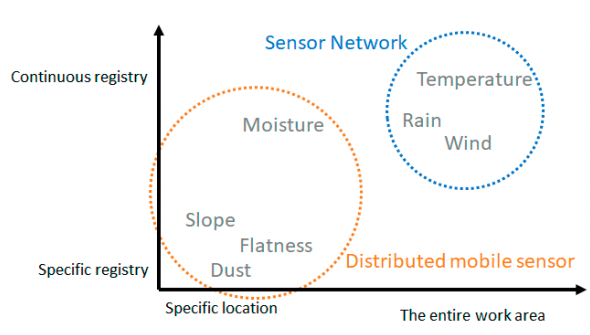

Figure 5. Classification of variables by extension and temporal distribution

As shown in the Figure 5, two distinct groups of variables can be identified. For those that require the collection of information on more or less extensive surfaces, we propose the use of sensor networks. Sensor networks allow covering large areas easily since they use an ad-hoc network that does not require support infrastructure, they are flexible, easy to deploy and self-configurable. This makes sensor networks a suitable proposal for variable and poorly controlled environments, such as this field.

For example, an operator may position the movable sensor on the surface of the roof to check the soil moisture at a point or its inclination. Unlike sensor networks, these distributed sensors work independently and do not require other sensors to perform their function. Like every node in the sensor network, any distributed sensor has various capture modules, as well as communication, storage, and processing ability. A general outline of the distribution of sensors on a roof is shown in Figure 6.

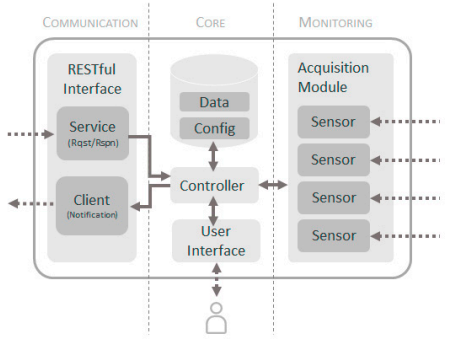

Figure 7. Architectural model of the sensors

Figure 7 shows the architectural model of the sensors. In this model three clearly differentiated parts are distinguished. A monitoring block composed of an Acquisition Module that coordinates the monitoring of all variables. This module integrates the various sensing modules that perform specific acquisition tasks for each variable (temperature, humidity, wind, etc.). The system can incorporate as many sensors as variables need to be monitored, so that the proposed objectives of flexibility and generality can be achieved.

INTEGRATION OF FLAT ROOFS EXECUTION PROCESS RESOURCES

First, the model has been based on the proposal of a digital LPS system (A in Figure 9), implemented through a friendly interface based on Web technologies. The interface provides a metaphor for “Kanvas” and “post-it” that includes a panel where with a simple process of “drag and drop” activities and tasks for each week are easily distributed.

The present proposal includes the necessary functionality in the LPS to incorporate such information in the process. Then, it has been defined a business rules engine responsible for determining the feasibility of tasks execution, connecting the LPS module and the sensor system. The Business Rules Engine is composed of a set of functional elements that are detailed below (B in Figure 9).

Finally, information to guide the workers involved is necessary, all this through a proposal that makes the complexity of the system transparent and with barely intrusive characteristics in the daily reality of workers. For this, the model has been based on two modules of interaction (C in Figure 9).

IMPLEMENTATION, TESTING AND VALIDATION

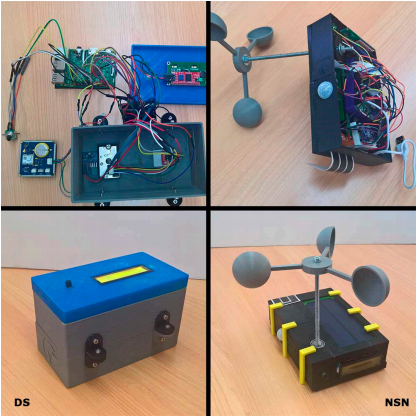

Figure 10. Picture of the implemented sensing system prototype

Since all the devices will be used outdoors, a hermetic encapsulation was made to protect them from the sun, rain and humidity. This encapsulation was custom designed and printed using a 3D printer. The wind turbines were also printed in 3D, and together with a photo interruptor for the count of steps, make up a wind sensor. Moreover, a sampling is performed for 5s to determine the speed, and the number of steps is transformed into velocity by a factor determined by a previous calibration. Figure 10 shows the final results of the prototypes for DS and NSN.

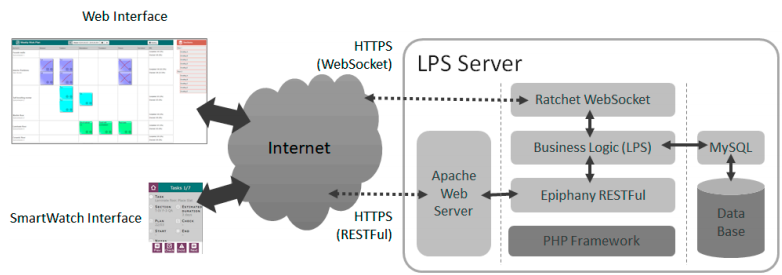

Figure 12. Prototype LPS

For the development of the prototype of an LPS system, a design based on Web Technology was chosen. This allows us to achieve the goals of ubiquitous access, enabling anytime, anywhere access to updated information about construction work. It was decided to use REST style Web Services, which has allowed its easy integration with the acquisition system. Authentication was achieved through JSON Web Token (JWT). The development has been done using PHP, using the Epiphany library for the implementation of web services, Apache web server as HTTP server and MySQL as DBMS (Figure 12).

Each entity in the LPS DB (activity, task, restriction, . . .) was implemented as a RESTful service, to be consumed by different clients. Additionally, so that synchronization between all elements that access LPS is instantaneous, and the server is not saturated through an access based on pooling models, a channel based on the technology Web Socket was incorporated to allow a bidirectional communication with the server.

Figure 13. Test scenario in a real environment

Two test scenarios destinations were designed to validate the research. One of them was developed in a laboratory to validate the system in a controlled environment, and to measure the performance of the prototypes. In addition, stress tests were performed to know the maximum limits and capacities of the proposal. Another scenario (Figure 13) was designed in a realistic environment, setting the prototype in motion in a real environment during a flat roof construction process.

CONCLUSIONS

This paper analyzes how a high percentage of the defects detected during the use phase of buildings are due to mistakes made at the construction phase of the project. These errors often occur because of the absence of control systems during the construction phase and the lack of information related to the physical variables of the environment when tasks are performed. This information determines the suitability of context to perform these tasks or on the contrary paralyze works.

This work is focused on the flat roof construction process since according to the MUSAAT Insurance Foundation, it represents the activity with the second greatest number of defects related to the above problem. Therefore, the present work proposes a new integrated management model to improve efficiency in the construction process, specifically the construction process of flat roofs, reporting the following benefits.

- The model includes information about variables of the physical environment that affect the quality of the construction during the execution phase.

- Updated information about variables is automatically acquired and provided through intelligent sensors networks and distributed sensors offered as services.

- The proposal includes a novel sensor system specifically designed for the construction environment.

- The model integrates workers and autonomous systems into the process transparently through IoT solutions and integration techniques. This allows guiding workers through the construction tasks from the context information of the worker’s environment.

- The solution provides traceability throughout the flat roof construction process.

The proposed model is based on the use of the LPS methodology as a task management system, focused specifically on the Weekly Work Plan phase. The model includes the management of restrictions or suitability when tasks are performed, through a sensor system that acquires context information offering it to workers at all times. This information allows guiding workers along with the construction process through IoT solutions and mobile devices.

As a result, a prototype of the proposed model was made to validate the feasibility of the system in a real construction environment. This allowed us to know how the model behaves in presence of different changes of variables in a real environment, notifying at all times to all the workers involved, in an unattended and remote way, if tasks could be performed or not. In addition, information was integrated into the Kanvas system of the LPS providing site managers a global view of the state of work, updated at all times and from any place.

Finally, after the validation we concluded that information about the management of tasks and the context variables was available during the execution process carried out in the validation, and it will allow an easier identification of possible improvements of the process. As future work, an extension of this management flat roof construction process model to other phases of a construction project will be developed. Likewise, automation capabilities and traceability processes will be increased by using Business Process Management paradigm as a backbone.

Source: University of Alicante

Authors: María Dolores Andújar-Montoya | Diego Marcos-Jorquera | Francisco Manuel García-Botella | Virgilio Gilart-Iglesias

>> Latest Sensor based IoT Projects for Engineering Students

>> 200+ IoT Led Engineering Projects for Students

>> IoT Environmental Monitoring System for Smart Cities Projects