ABSTRACT

The Internet of Things (IoT) scenario is strongly related with the advance of the development of wireless sensor networks (WSN) and radio frequency identification (RFID) systems. Additionally, in the WSN context, for a continuous feed, the integration of textile antennas for energy harvesting into smart clothing is a particularly interesting solution when the replacement of batteries is not easy to practice, such as in wearable devices.

This paper presents the E-Caption: Smart and Sustainable Coat. It has an embedded dual-band textile antenna for electromagnetic energy harvesting, operating at global system for mobile communication (GSM) 900 and digital cellular system (DCS) 1800 bands. This printed antenna is fully integrated, as its dielectric is the textile material composing the coat itself. The E-Caption illustrates the innovative concept of textile antennas that can be manipulated as simple emblems.

Seven prototypes of these “emblem” antennas, manufactured by lamination and embroidering techniques are also presented. It is shown that the orientation of the conductive fabric does not influence the performance of the antenna. It is also shown that the direction and number of the stitches in the embroidery may influence the performance of the antenna. Moreover, the comparison of results obtained before and after the integration of the antenna into cloth shows the integration does not affect the behavior of the antenna.

MATERIALS AND METHODS

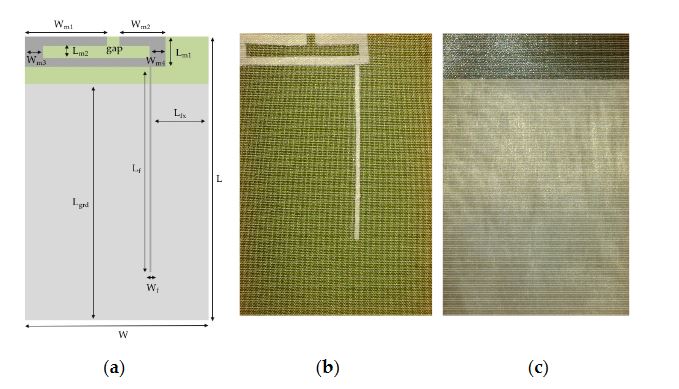

Figure 1. Textile antenna. (a) Design of the dual-band antenna; (b) Front; and (c) Back

This paper is based on the dual-band textile antenna for GSM900 and DCS1800 frequency bands proposed in that is shown in Figure 1 and which dimensions are given in Table 1 below. The next subsections will analyze the manufacturing process of making this antenna, presenting seven prototypes, made using two different manufacturing techniques: thermal adhesive lamination and embroidering. Further, the integration of the antenna into a smart coat, by fully embedding it into the material constituting the coat, is described.

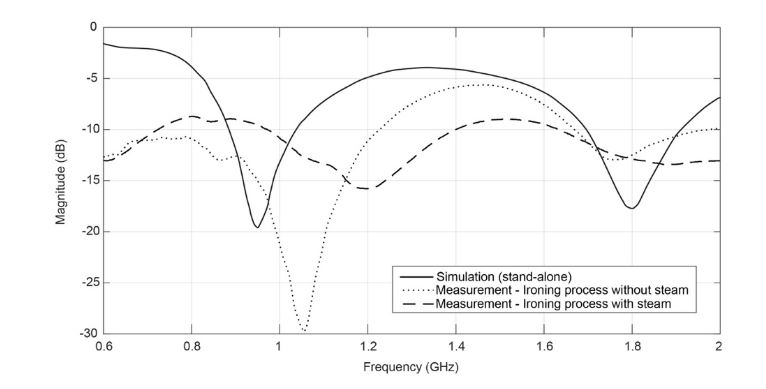

Figure 2. Comparison between ironing processes with, and without, steam

According to the measured results presented on Figure 2, one can see a higher frequency shift in the antenna made using steam in the ironing process. In order to investigate the cause of this shift, the thickness of the antenna was measured, using Kawabata’s Evaluation System (KES) for fabrics (KES-F-3 Compressional Tester).

RESULTS

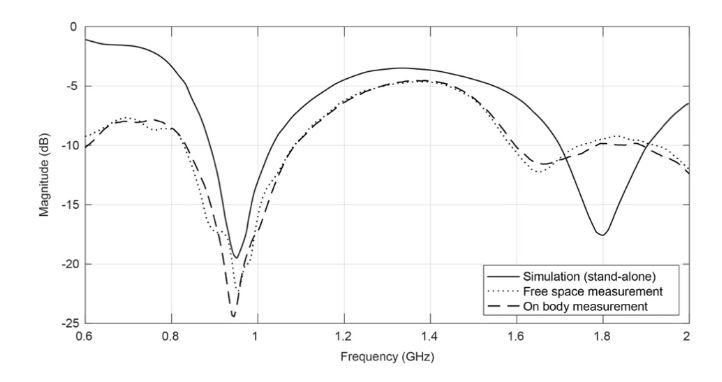

Figure 10: Simulated and measured return loss, before/ after the integration on clothing

Figure 10 presents the variation in the S11 parameter obtained through numerical simulation and measured in free space, before and after the integration into the smart coat. It is possible to see the agreement between the simulated and measured values even in the on-body measurements.

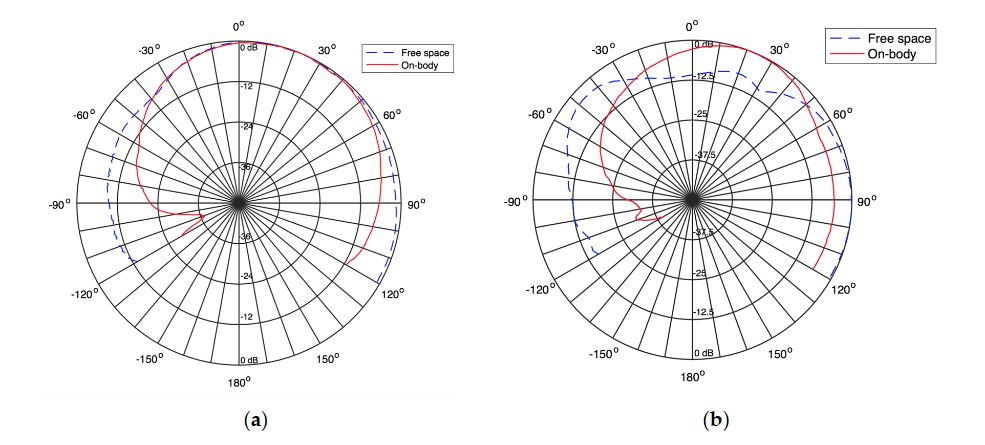

Figure 11. Measured radiation pattern of the textile antenna into the coat at (a) 900 MHz and (b) 1800 MHz

The on-body antenna performs differently. Since the human body is conductive, it absorbs and reflects radio frequency waves. The results on Figure 11 show that when the body is behind the test antenna, at 30° broadside, a slight increase in gain is measured. However, when the body is between the probe and the test antenna, at 160°, it will absorb a high amount of radiation and will reflect the rest in the opposite direction, shielding the test antenna and, thus, create a null of radiation at this point. This happens for both frequencies, being clearer at 1800 MHz.

DISCUSSION

In the future, garments will not only communicate social conditions or protect the human body against the extremes of nature, but will also provide information and communication tools. Clothes are becoming able to communicate wirelessly without the need of large and expensive equipment. This is possible because textile technologies can produce new types of sensors and antennas that are so small, flexible, and inexpensive that they can be applied in different types of clothing, shoes, and accessories.

CONCLUSIONS

Embedding antennas in clothing contributes for the advance of the integration of electronic devices in less obtrusive way making the smart clothes more comfortable. In the E-caption, the antenna is manufactured directly on the clothing, having a continuous dielectric substrate made with the textile materials composing the coat. Therefore, a continuous substrate of the antenna does not influence its performance.

Moreover, the presented results show that, despite the masses of the coat and of the body influencing the radiation characteristic of the integrated antenna, it still shows a nearly omnidirectional pattern. This work shows that “emblem” antennas, including the ones having ground planes, may be manufactured by lamination and embroidering techniques. When laminating, the ironing process without steam seems to be preferable as it better preserves the electromagnetic performance of the materials.

Additionally, this work shows the orientation of the conductive fabric used for the patch is not influencing the performance of the laminated antenna. In addition, it shows the direction and number of the stitches in the embroidery may contribute to increasing the conductivity of some elements, thus improving the performance.

Source: University Da Beira

Authors: Caroline Loss | Ricardo Goncalves | Catarina Lopes | Pedro Pinho | Rita Salvado

>> More Wireless Sensor Networks Projects Abstract for Engineering Students

>> More Wireless Embedded Projects for Final Year Students