ABSTRACT

Several research works have been carried out to study properties of concrete containing crumb rubber (rubbercrete) as a partial replacement to fine aggregate. Rubbercrete exhibits numerous benefits compared to conventional concrete such as lower in density, increased ductility, enhanced plastic capacity, higher toughness, higher impact resistance, better chloride penetration, lower thermal conductivity, higher noise reduction factor and better electrical resistivity.

It has also been known to have better energy dissipation, durability and damping ratio. However, the main drawbacks of rubbercrete are decreasing in strengths and Young’s modulus. Therefore, to improve strengths of the rubbercrete, the crumb rubber has been pre-coated with nano-silica. Results have revealed that nano-silica modified rubbercrete can be produced with high strengths due to the densification of the interfacial transition zone (ITZ) and refining pore system of the rubbercrete.

MIXTURE PROPORTIONS

Five rubbercrete dry mixtures with different nano-silica additives (0%, 1%, 2%, 3%, 4% and 5%) were prepared, cast under pressure and tested at age of 28 days. The mixtures contained 10% of crumb rubber replacement to fine aggregate by volume and amount of water equal to 8% of the total batch weight. Compressive strength, Field Emission Scanning Electron Microscopy (FESEM), and Mercury Intrusion Porosimetry (MIP) were conducted on samples from each mixture as shown in Table 1 and the mixtures proportions are shown in Table 2.

TEST RESULTS AND ANALYSIS

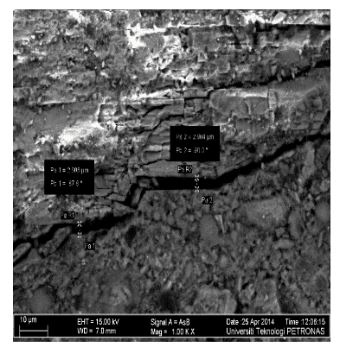

Figure 1: FESEM for NS0 CR10

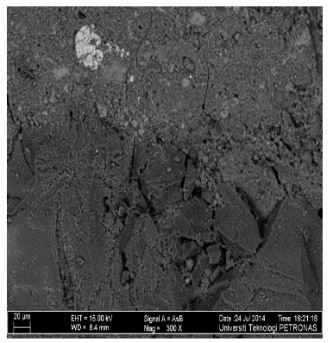

Figure 2: FESEM for NS1 CR10

Therefore, to enhance the compressive strength of rubbercrete, ITZs have to be densified, in other words; enhancing bonding between aggregates and cement paste. Adding NS to rubbercrete has lead to improve significantly the compressive strength. This is due to chemical reactivity of the NS with Ordinary cement. Whereas, NS react with Ca(OH)2 (hydration product of Ordinary cement) in the pore system and ITZs to produce C-S-H gel which is responsible on strength. This leads to densifying of ITZs and eventually increasing the compressive strength as shown in Table 3 and Figures 1 to 5.

CONCLUSION

Rubbercrete has many advantages in comparison with the conventional concrete. However, it is usage in the construction industry has been limited due to its poor compressive strength. Therefore, producing rubbercrete with good strength, and without additional cement, will lead to better consideration of rubbercrete in the construction industry. Using of nano-silica in rubbercrete mixtures has lead to improving the strength due to the physicochemical.

Whereas, through chemical effect, nano-silica reacts with Ca(OH)2 to produce C-S-H gel which responsible for strength and through physical effect, the nano particles have filled up nano voids and also pores in the hardened cement paste. Both effects of nano-silica has led to modify the microstructure of the rubbercrete and subsequently increasing the compressive strength.

Source: University Teknologi Petronas

Authors: Bashar S. Mohammed | Muhd Fadhil Nuruddin | Nasir Shafiq